Durable, High-Precision Copper Etching

Photochemical etching is a precise process ideal for creating intricate patterns on copper and copper alloys.

Copper is softer than other metals, so although it is easy to etch, cutting methods that use heat or force are unsuitable as they can damage the component.

Photochemical etching is ideal as it does not affect the mechanical properties of the copper, and the etched components are free from burrs.

At Elcon Precision, we combine photolithography and chemical etching to deliver durable, high-precision components.

- A photoresist mask is applied on the copper metal substrate.

- This resist is exposed to UV light through a photoresist mask or stencil that contains the desired pattern.

- The substrate is developed to remove the unexposed resist, leaving only the patterned areas protected by the cured resist.

- The substrate masked with the photoresist is immersed in an etching solution, typically ferric chloride, hydrogen peroxide, nitric acid, or hydrogen fluoride.

- The etchant reacts with the copper parts unprotected by the mask, dissolves it and creates the desired pattern.

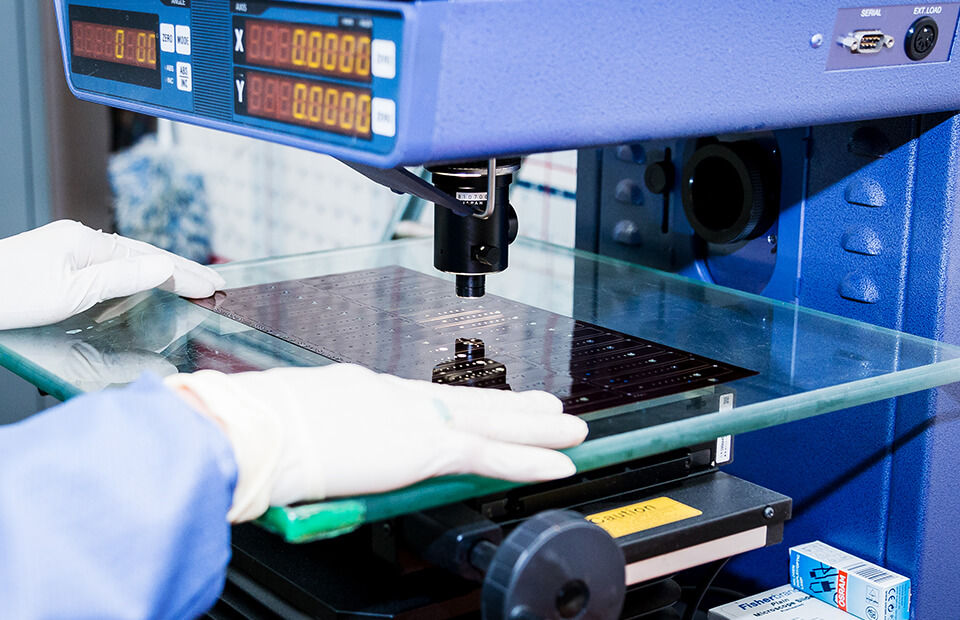

Our precise metal etching process allows us to monitor and control parameters such as etchant concentration, temperature, and etching time. This results in long-lasting and high-quality copper components.

Long-Lasting Copper & Copper Alloys

Copper is a versatile and durable metal, making it ideally suited for applications that require mechanical strength, material integrity, and longevity.

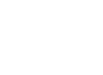

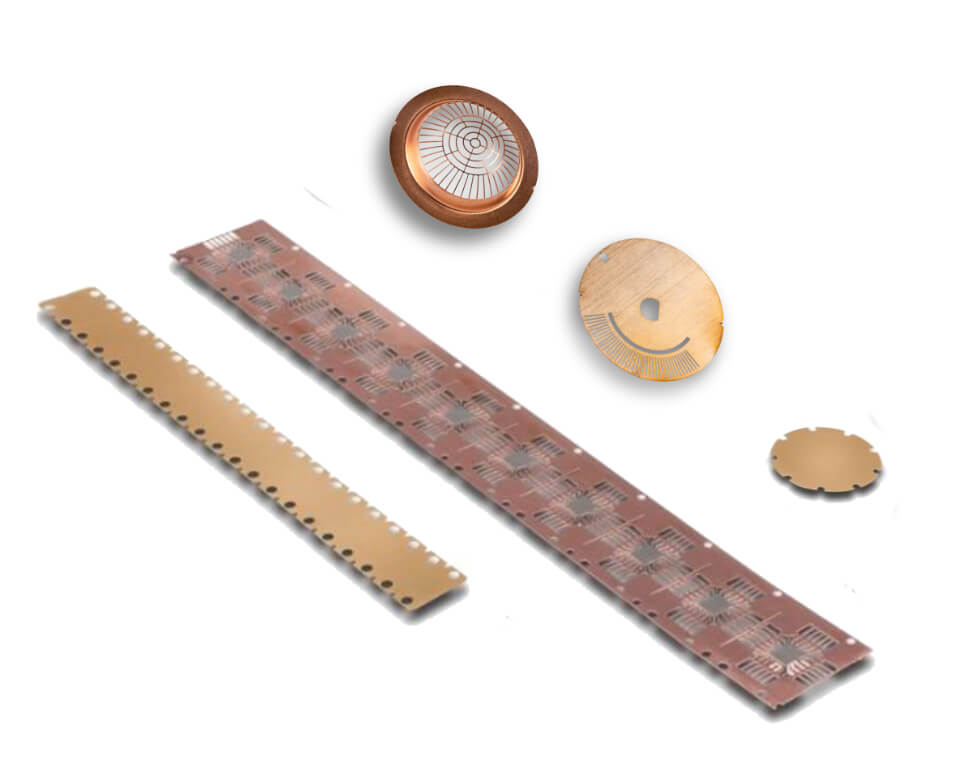

We manufacture high-precision copper parts that require fine and detailed etching, such as microelectronic components, semiconductors, circuit boards, or PCBs.

There are many advantages to using copper etching for reliable and durable components:

- Its high electrical and thermal conductivity allows copper components to handle high voltages and currents.

- The precision of our copper etching process allows us to create intricate and precise patterns with high accuracy, tight tolerances, sharp edges, and smooth surfaces.

- The high level of precision, control, and monitoring means that copper etching delivers a consistent quality of components from batch to batch, which is critical for industries that require tight quality control and uniformity, such as electronics and aerospace.

- The copper etching process has a low set-up cost, no expensive tooling, and minimal material wastage, making it highly cost-effective.

The copper etching process enables us to manufacture small batches or high volumes at fast lead times, within days.

Our Etching Capabilities

- Etching up to 0.025″-thick sheets ranging up to 22×12 inches

- Fabrication of thicker sheets up to 2mm

- Tolerances of ±.0005 inches in many applications

Copper Applications

- Microelectronics

- Fuse links

- Busbars

- Carriers and ribs

- RF/EMI shielding

- Leadframes

- Grounding clips

- Microwave device components

- Washers

- Conductors

- Wave springs and washers

- Electronic circuits

- Heat sinks