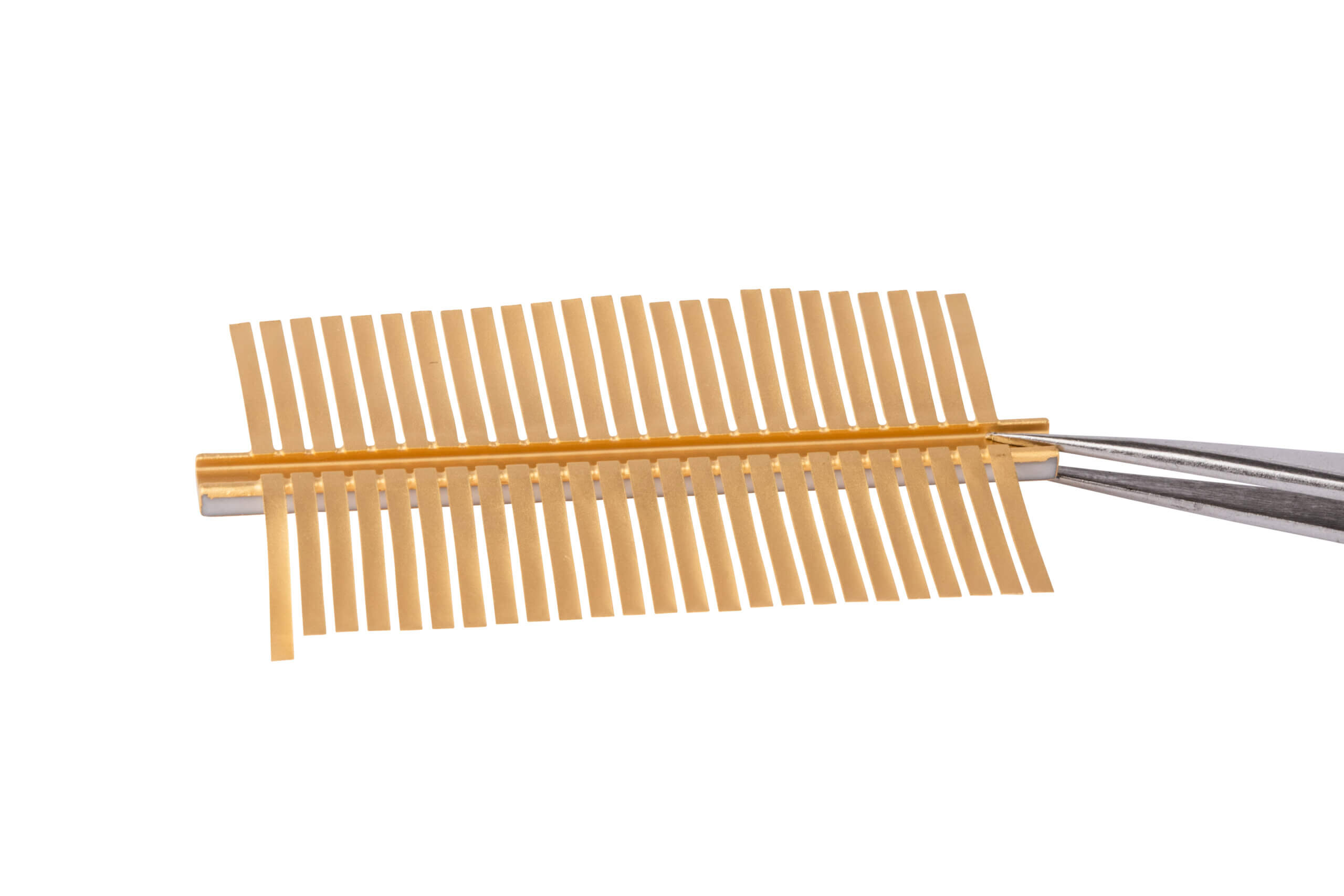

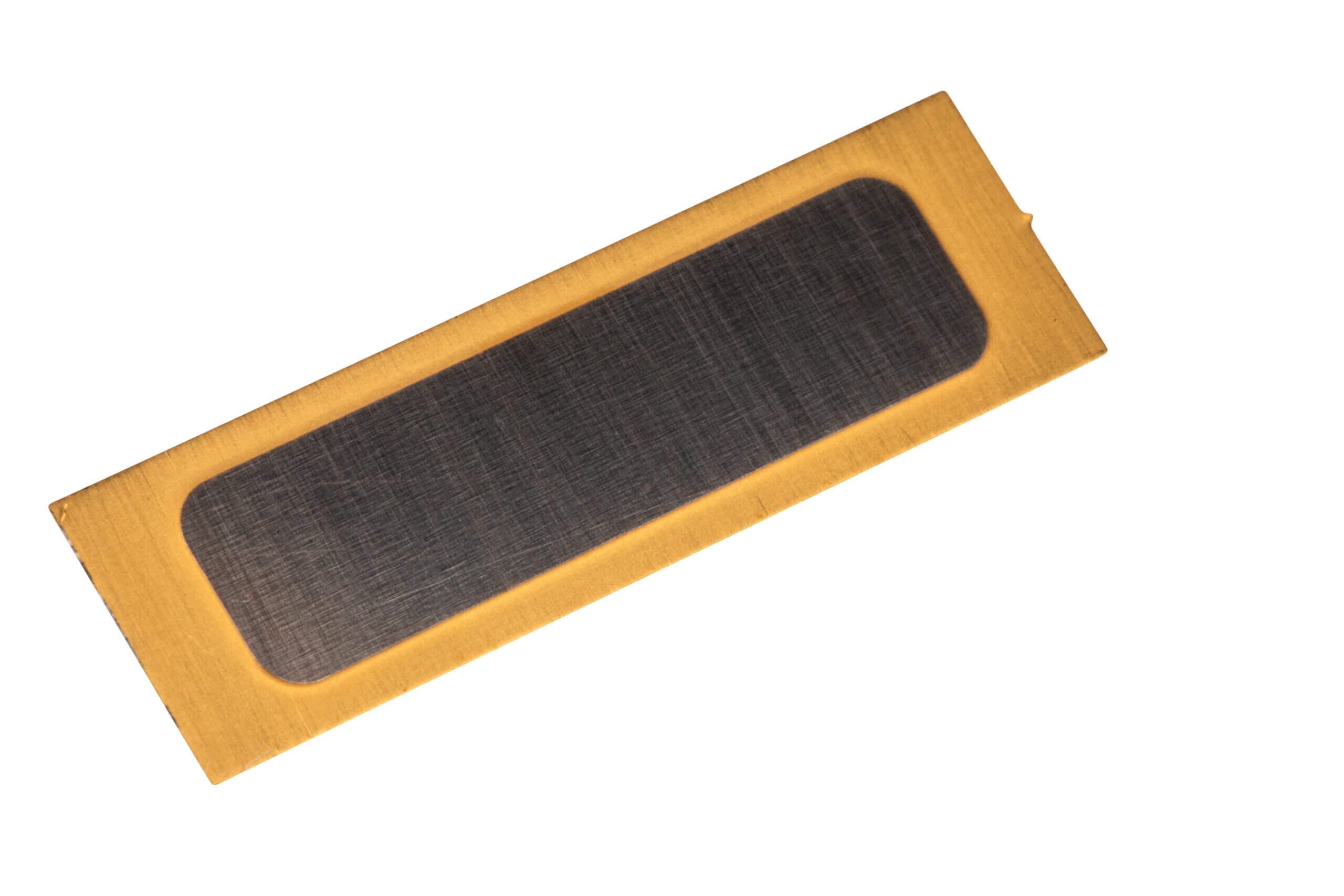

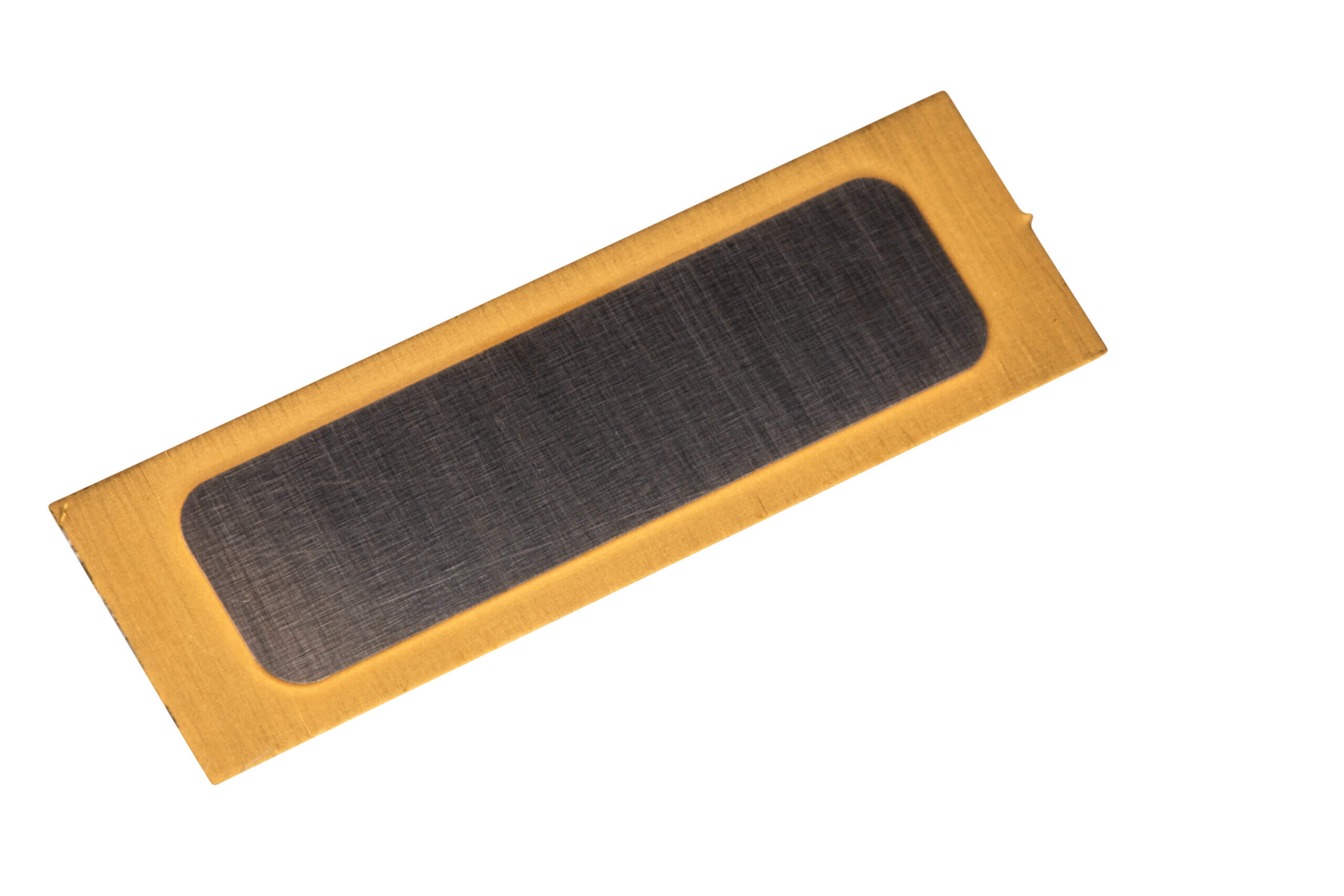

Our Electro & Electroless Precision Plating Process

We specialize in nickel boron and nickel phosphorous electroless plating and are capable of plating parts as wide as 12 inches and as high as 18 inches in our large-capacity barrel and rack tanks. We perform nickel, gold, silver, and copper electrolytic plating with a thickness of up to 200µin, and also offer selective plating when two different plated metals are needed on the same part. We plate most metals as well as metallized alumina, beryllia and other ceramics.

To ensure parts are free from dirt and other surface contaminants, our team performs pre-plating operations that include abrasive blasting, caustic and acid cleaning, spray washing, and ultrasonic cleaning. Plated parts are visually inspected and thoroughly tested for plating adhesion, coating thickness, corrosion resistance, hardness and porosity, all combining to produce high-quality and reliable components designed to work the first time and every time.

Benefits

- Brazeability

- Solderability

- Conductivity

- Corrosion protection

- Compliance with industry standards

Capabilities

- Electro and electroless plating

- Selective and spot plating

- Abrasive blast

- Acid rinse

- Spray washing

- Stripping

- Thermal, ultrasonic and vapor cleaning

- Shot & glass bead peening

- Testing

- Adhesion

- X-ray fluorescence (XRF)

- Hardness

- Porosity

- Corrosion resistance

Specifications

View applications for electro and electroless plating, the materials we use, example products, and more below.